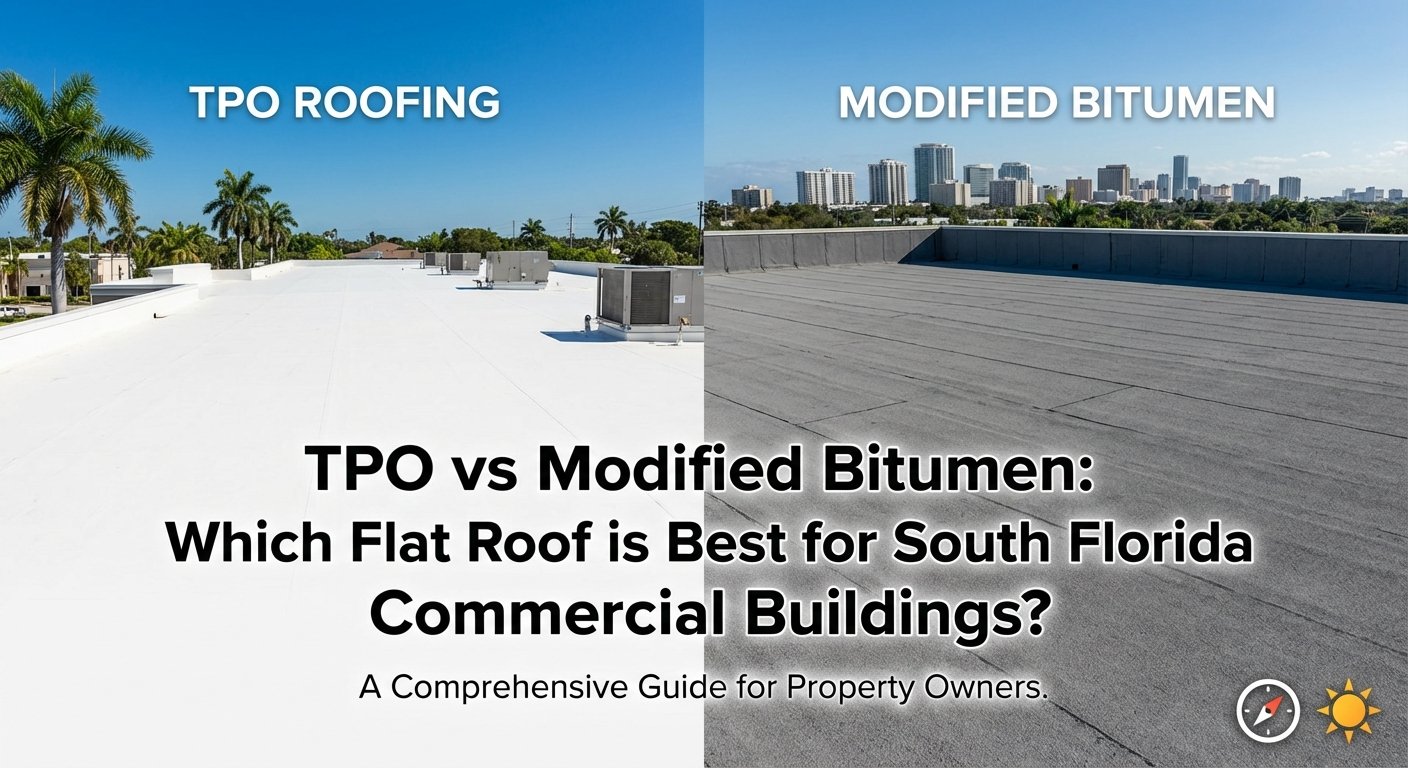

TPO vs Modified Bitumen: Which Flat Roof is Best for South Florida Commercial Buildings?

When your commercial building’s flat roof starts showing its age—ponding water after summer storms, cracks in the surface, or energy bills climbing higher each month—you’re facing a decision that will affect your property for the next 15 to 30 years. As a commercial roofing contractor South Florida property owners have trusted since the 1950s, we’ve installed hundreds of flat roofing systems, and the question we hear most often is: “Should I go with TPO or modified bitumen?”

There’s no one-size-fits-all answer, but there is a right answer for your specific building, budget, and goals. Let’s walk through what you actually need to know about these two popular commercial roofing materials Florida businesses rely on.

Understanding Your Flat Roof Options in South Florida’s Climate

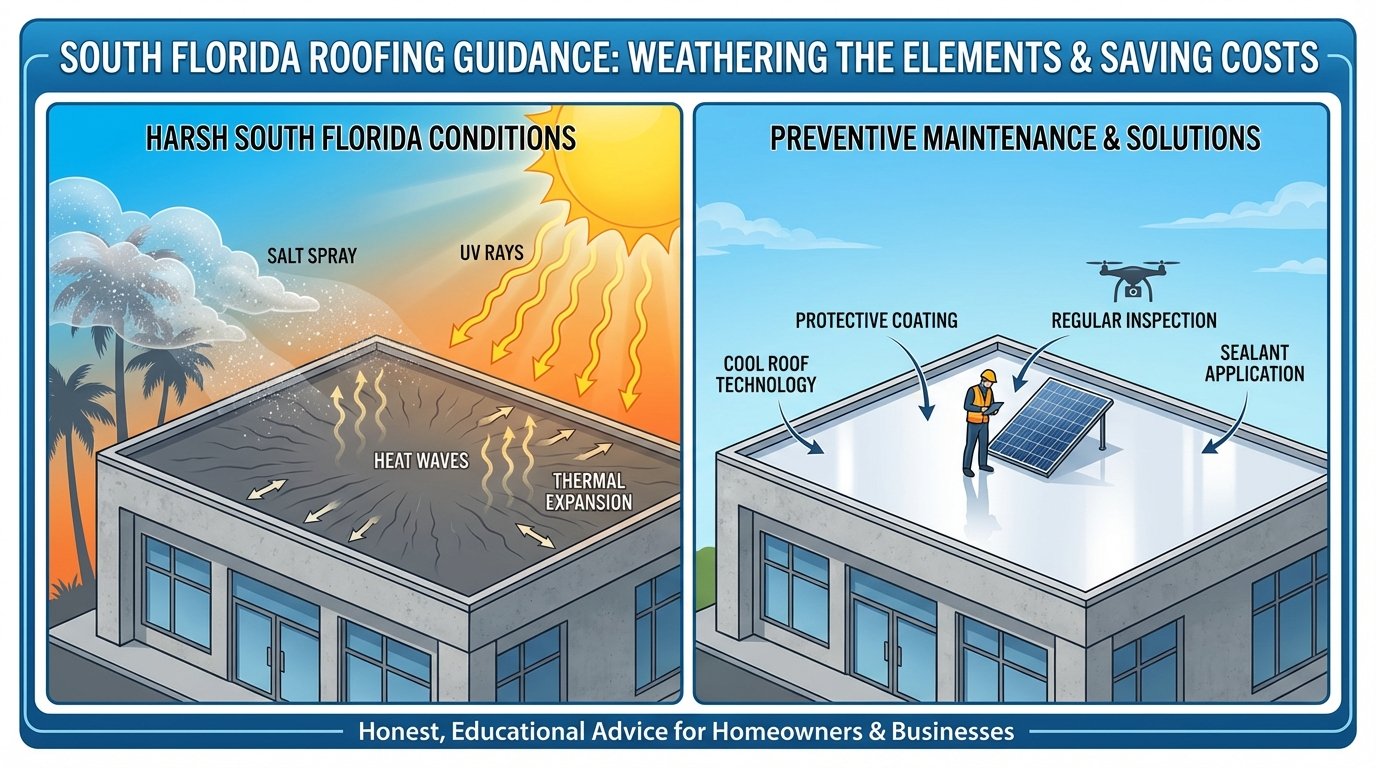

South Florida puts commercial roofs through challenges that buildings in other parts of the country never face. We’re talking about 250+ days of intense UV exposure annually, salt air eating away at materials along the coast, thermal cycling that expands and contracts roofing membranes daily, and hurricane-force winds that test every seam and fastener.

Your flat roof isn’t just keeping rain out—it’s your first line of defense against one of the harshest commercial roofing environments in the United States. That’s why choosing between TPO and modified bitumen isn’t about which material costs less upfront; it’s about which system will perform best for your specific situation over its entire lifespan.

Modified Bitumen: The Proven Workhorse

Modified bitumen has been protecting commercial buildings in South Florida since the 1970s. If you’re old enough to remember when they called it “mod bit,” you know this isn’t some untested trend—it’s a time-tested system that’s been refined over five decades.

How Modified Bitumen Works

Modified bitumen flat roofing consists of asphalt that’s been modified with rubber (SBS) or plastic (APP) polymers, then reinforced with fiberglass or polyester mats. These sheets are typically torch-applied, heat-welded, or adhered with cold adhesive to create a multi-layer waterproof membrane.

The beauty of this system is its redundancy. Most modified bitumen installations use at least two layers—a base sheet and a cap sheet—giving you multiple barriers against water intrusion. When installed by an experienced flat roof contractor South Florida businesses can depend on, these seams are incredibly strong and reliable.

Modified Bitumen Advantages in Florida

- Puncture resistance: If your roof sees foot traffic for HVAC maintenance or you have equipment installations, modified bitumen’s tough surface handles abuse better than most alternatives

- Heat welding creates superior seams: When properly torch-applied, the seams are often stronger than the membrane itself—critical during hurricane-force winds

- Proven track record: We have modified bitumen roofs we installed 25+ years ago still performing well with proper maintenance

- Repairable: When issues occur, repairs are straightforward and can often be done without replacing large sections

- Multiple application methods: Can be torched, mopped, or cold-applied depending on your building’s needs and local fire codes

Modified Bitumen Considerations

Modified bitumen is typically black or has limited reflective options compared to TPO, which means it absorbs more heat. In South Florida’s brutal summers, this translates to higher cooling costs unless you opt for a reflective coating or granulated cap sheet. The material also requires skilled installation—torch application needs experienced crews who understand fire safety and proper heat welding techniques.

TPO: The Energy-Efficient Alternative

Thermoplastic Polyolefin (TPO) roofing has gained significant market share over the past two decades, and for commercial property owners concerned about energy costs, it’s easy to understand why. As a TPO flat roofing contractor who’s installed systems ranging from small offices to 100,000+ square foot warehouses, we’ve seen this material evolve and improve substantially.

How TPO Roofing Works

TPO is a single-ply membrane—typically white or light gray—that comes in rolls ranging from 6 to 20 feet wide. The seams are heat-welded together using hot air equipment, creating watertight bonds. The membrane is usually mechanically fastened or fully adhered to the roof deck with insulation layers underneath.

TPO Advantages for South Florida Buildings

- Energy efficiency: That bright white surface reflects up to 85% of the sun’s rays, dramatically reducing cooling costs—a significant consideration when your AC runs 10+ months annually

- Meets Energy Star requirements: Important for buildings seeking LEED certification or utility rebates

- Lighter weight: Easier to transport to rooftops and less structural load than multiple modified bitumen layers

- Chemical resistance: Performs well in environments with grease or other chemicals (restaurants, manufacturing facilities)

- Faster installation: Single-ply systems typically install quicker than multi-layer modified bitumen, reducing labor costs

- No open flames: Hot air welding eliminates fire risks associated with torch-applied systems

TPO Considerations

TPO technology is still evolving. Early generation TPO systems (pre-2010) had some performance issues, though current formulations are substantially improved. The material is more susceptible to punctures than modified bitumen, so heavy foot traffic or sharp objects require extra caution. Hot air welding requires skilled technicians—poorly welded seams are a common failure point we see when called for repairs on systems installed by less experienced contractors.

What About EPDM?

While we’re comparing options, we should mention EPDM (rubber) roofing. EPDM flat roof installation remains popular nationwide, but it’s less common on South Florida commercial buildings for specific reasons. EPDM performs exceptionally well in cooler climates but faces challenges with our extreme heat and UV exposure. The seams are typically adhered with tape or liquid adhesives rather than heat-welded, which can be a vulnerability point in our climate.

That said, EPDM can be appropriate for certain applications, particularly where budget is the primary concern or for buildings with complex roof geometries where its flexibility is advantageous.

Making the Right Choice for Your Building

After evaluating hundreds of commercial properties across South Florida, here’s how we typically guide property owners through this decision:

Choose Modified Bitumen If:

- Your roof experiences regular foot traffic or equipment maintenance

- You have a proven modified bitumen roof and want consistency

- Your building has complex penetrations or roof details

- Initial cost is your primary concern (modified bitumen is often 10-20% less expensive upfront)

- You prefer time-tested technology over newer materials

Choose TPO If:

- Energy costs are a significant concern for your operation

- You want the fastest possible installation

- Your building requires energy-efficient commercial roofing for certification or rebates

- You have a relatively simple roof design with fewer penetrations

- You’re willing to invest slightly more upfront for long-term energy savings

The Real Cost Comparison

In 2026, you’re looking at roughly $4.50-$7.00 per square foot for modified bitumen and $5.00-$8.00 per square foot for TPO, including removal of one existing layer, basic insulation, and installation. These ranges vary based on roof size, complexity, insulation requirements, and current material costs.

But here’s what matters more than those initial numbers: the total cost of ownership. A TPO roof might cost $15,000 more upfront on a 30,000 square foot building, but if it saves you $200-300 monthly on cooling costs, you’ve recovered that investment in 5-7 years—and the roof should last 20-25 years with proper maintenance.

Conversely, if you’re running a warehouse that’s not climate-controlled, spending extra for energy-efficient commercial roofing doesn’t make financial sense. Modified bitumen would serve you better.

Installation Quality Matters More Than Material Choice

Here’s something we tell every property owner: the best roofing material installed poorly will fail faster than a decent material installed correctly. We’ve seen $200,000 TPO roofs fail within five years due to improper seam welding, and we’ve seen 30-year-old modified bitumen still going strong because it was installed right from day one.

When evaluating flat roof contractor South Florida options, verify:

- Manufacturer certifications specific to the products they’re installing

- At least 10+ years of commercial roofing experience in South Florida specifically

- References from similar commercial properties

- Proper licensing and insurance (never negotiate on this)

- Detailed specifications explaining exactly what materials and methods they’ll use

Maintenance Extends Either System’s Lifespan

Regardless which material you choose, plan on bi-annual inspections and proactive maintenance. We recommend inspections after hurricane season (November) and before summer storms (May). These checkups catch small issues—a loose seam, a developing crack, clogged drains—before they become $50,000 problems.

Both TPO and modified bitumen can often be extended 5-10 years beyond their typical lifespan with proper maintenance and restoration coatings. That maintenance relationship is why working with an established commercial roofing contractor South Florida property owners can reach year after year matters so much.

Your Next Steps

If your commercial flat roof is approaching 15-20 years old, showing visible wear, or driving up energy costs, it’s time for a professional assessment. Don’t wait until you’re dealing with interior water damage and business interruption.

We offer honest evaluations of your existing roof—sometimes that means recommending repairs and another 3-5 years of service rather than immediate replacement. Our goal is helping you make the right decision for your building and budget, not pushing the biggest sale.

Whether you ultimately choose TPO, modified bitumen, or another solution, you deserve a commercial roofing contractor South Florida businesses can trust for straight answers, quality work, and service that extends decades beyond installation. That’s been our approach for over 70 years, and it’s why we have commercial clients we’ve served since the 1980s.

Contact us for a no-pressure roof assessment. We’ll evaluate your specific situation, explain your options honestly, and provide a detailed proposal that helps you make an informed decision. Your roof is too important for anything less than complete transparency.